How are our products coated?

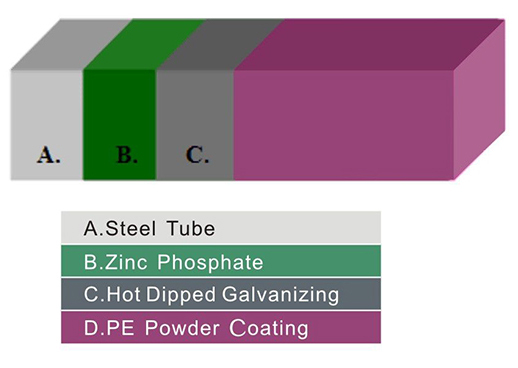

Each Panovic product is protected by multi-layer protective coatings to resist effects of weathering.To bring you the strongest and most durable railing and fence system on the market, our products are coated with AkzoNobel or DuPont powder coating that is loaded with UV inhibitors.

OPTION 1: Pre-galvanized + Zinc phosphate + Zinc-rich epoxy coating + AkzoNobel powder coating

|

|

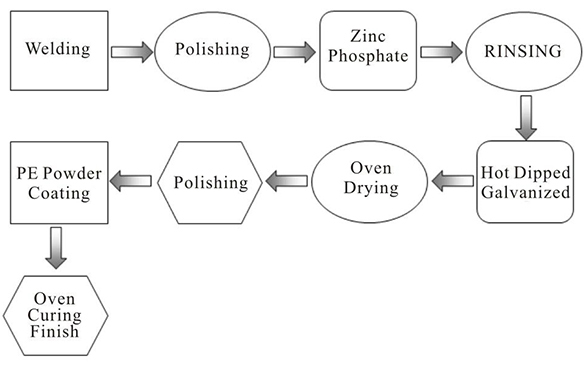

OPTION 2: Steel + hot dipped galvanizing + AkzoNbel powder coating

|  |

OPTION 3: Steel or pre-galvanized + Zinc phosphate + E-coat + AKzoNbel powder coating(NEW)

|

|

E-COAT AS ONE KIND OF PRIMER BEFORE POWDER COATING,

IT IS THE PRIMARY CORROSION PRETECTION LAYER.

| What is Electrocoating? In short, electrocoating (also called e-coating) is the process by which a metallic workpiece is submerged in a paint / water bath and electricity is used to deposit paint onto it. The electrodeposition process is the most automatic, controllable, and efficient method for applying a corrosion inhibiting primer to a metallic workpiece. History of Electrocoating This technology is not new. The first use of electrodeposition to apply an organic coating to metal occurred in the 1930’s. And that apply anti-corrosion primers to complex metal configurations, such a fully assembled automobile bodies originated in the early 1960's. Then in the mid-1970's, cathodic electrodeposition primers became available to the automotive industry. The advantages of the cathodic process and materials caused the rapid conversion within the automotive industry from the anodic electrodeposition and conventional spray application to the cathodic electrodeposition. And continuing today, we use it as a primer layer to iron railing. |

Advantages of Electrocoating Electrocoating is an immersion painting process in which charged paint particles are attracted to an oppositely charged metallic surface. Corrosion resistance is superior to other paint application methods because immersion E-coat provides a complete, uniform coating. Formation of protective films in highly recessed areas such as flanges and box sections provides critical corrosion protection. In the application of iron railing and fence, e-coat is applied between the phosphate and top coat. The e-coat layer is the primary corrosion. |

|